Mechanical Behavior Laboratory

Experimental investigations of the mechanical behavior of engineering materials emphasizing the fundamental relationships between microstructure and mechanical properties.

|

1. Plastic Deformation and the Onset of Plastic Instability

|

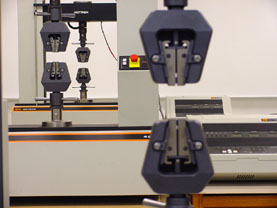

A view of the tensile testers used in this experiment. |

Back to top

2. Stress Relaxation in Polymers

Like metals polymers deform elastically and plastically but unlike metals they are highly anelastic. Anelasticity refers to a behavior where the recoverable stress is dependent on the deformation rate. For instance, the total stress will increase rapidly if a specimen is pulled quickly, not as fast if pulled slowly, and will even decrease if in the middle of the test we stop pulling on the specimen. In this experiment the students investigate this behavior by measuring the rate and magnitude of the relaxation of the stress. The stress relaxation behavior of an aluminum alloy is also evaluated to show that while metals do exhibit anelastic properties it is not as pronounced as in polymers and it happens much more quickly.

- Procedure - Notes and the complete procedure for this experiment.

Back to top

|

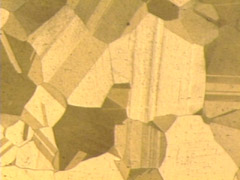

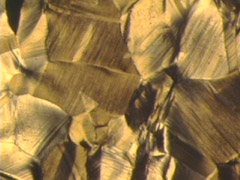

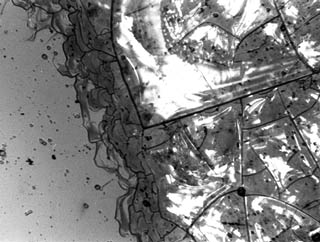

3. The Hall-Petch Relationship The two micrographs to the right show the microstructure at the polished and etched surface of a 70/30 brass tensile sample at the beginning and near the end of a tensile test. Note the surface roughness and the different directions of the deformation bands in each grain at the end of the test.

|

|

Back to top

|

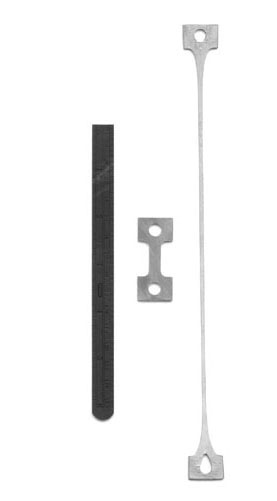

4. Superplasticity |

An example of the extraordinary tensile elongations possible with superplastic deformation. |

Back to top

|

5. The Ductile-to-Brittle Transition

|

The fracture surface of this Charpy impact specimen show that the fracture mode was a mixture of ductile (dull gray) and brittle (shiny, salt and peppery appearance). |

Back to top

|

6. Griffith Flaws in Brittle Materials

|

Superficial fractures caused by stresses resulting from ion substitution. The glass on the left is untreated. |

Back to top

Appendices

The appendices page at this web site offers a number of documents that you will find useful during and after the laboratory session. These include tables of materials properties, operating procedures for the equipment, and documents that will help you get the most out out your spreadsheet-based assignments and writing the laboratory reports. The documents you should look are:

- Spreadsheets Hints and Formatting

- Excel Reference (draft)

- Macromet 1 Operation (Hardness Tester)

- Macromet I Operation (Hardness Tester)

- Instron Operation, Methods 38 and 39 (Tensile Tester)

- Selected Symbols, Formulas, and Conversion Factors

- Mechanical Properties of Selected Materials

- The Optical Microscope

- Digital Image Capture, Polaroid DMC Version

- Enhancing Digital Images

- Metallographic Sample Preparation for 70/30 Brass

- Basic Statistics

- Measuring Grain Size

Back to top